Like model 5401 Plus, but with personalized battery recognition. The BCS data pro provides critical information about production processes through continuous monitoring and ensures the most efficient use of battery tools in series production.

You can find the current adapter list here (PDF file).

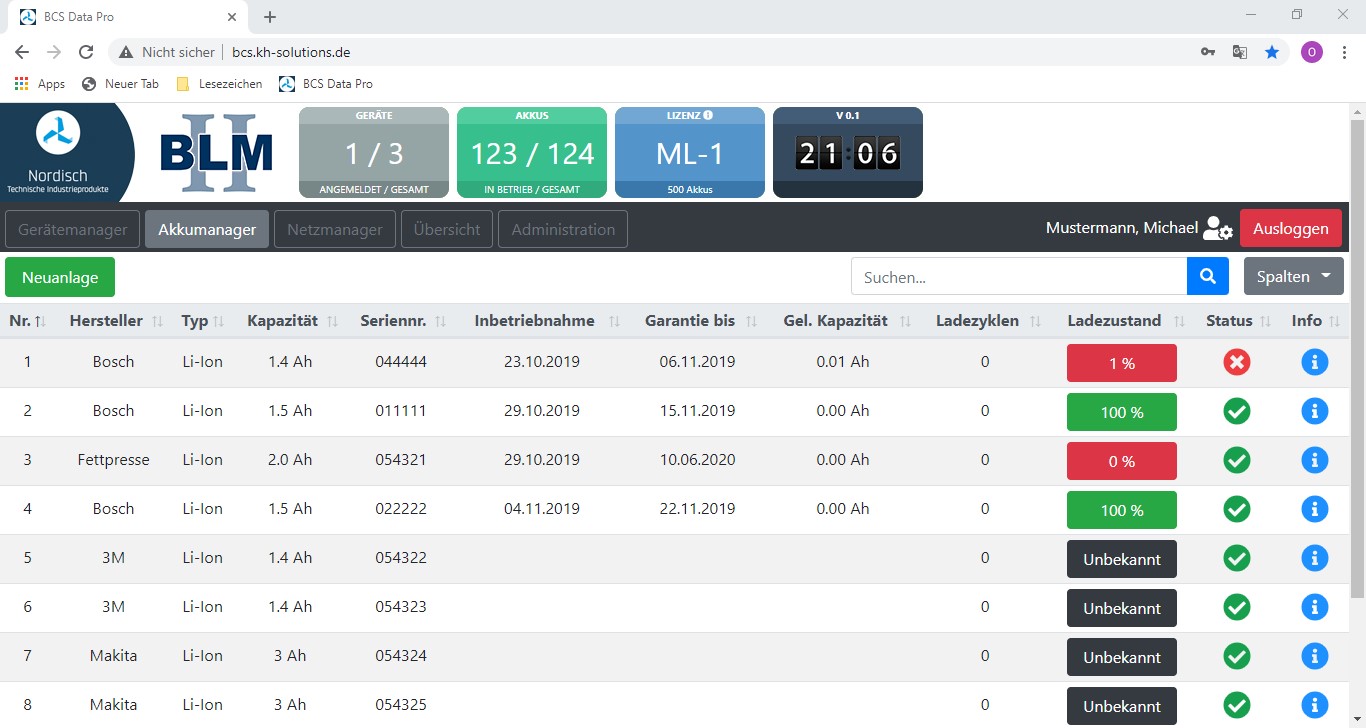

The BCS data pro ensures important information about the production processes through its continuous monitoring and guarantees the most effective use of battery tools within series production.

Charging each battery, detecting faults or defects. The positioning of your charging devices in the plant, as well as the exact number of batteries and charging devices used and available. You get the information you need, regardless of the manufacturer or cell technology of the battery!

In general, the modern design of the BSC series guarantees flexible expansion even in confined spaces (e.g., when stacking in a system cabinet) and provides the necessary heat dissipation with the integrated thermal management function to prevent premature aging of Li-Ion batteries. The interface on the back is unique, allowing both the renewal of charging parameters and monitoring of the status during charging if necessary. This makes this device certainly unique in terms of future-proofing new battery technologies on the market. Through a software update of the base unit and adapters, the user can charge future battery types of the next generation that are currently unknown.

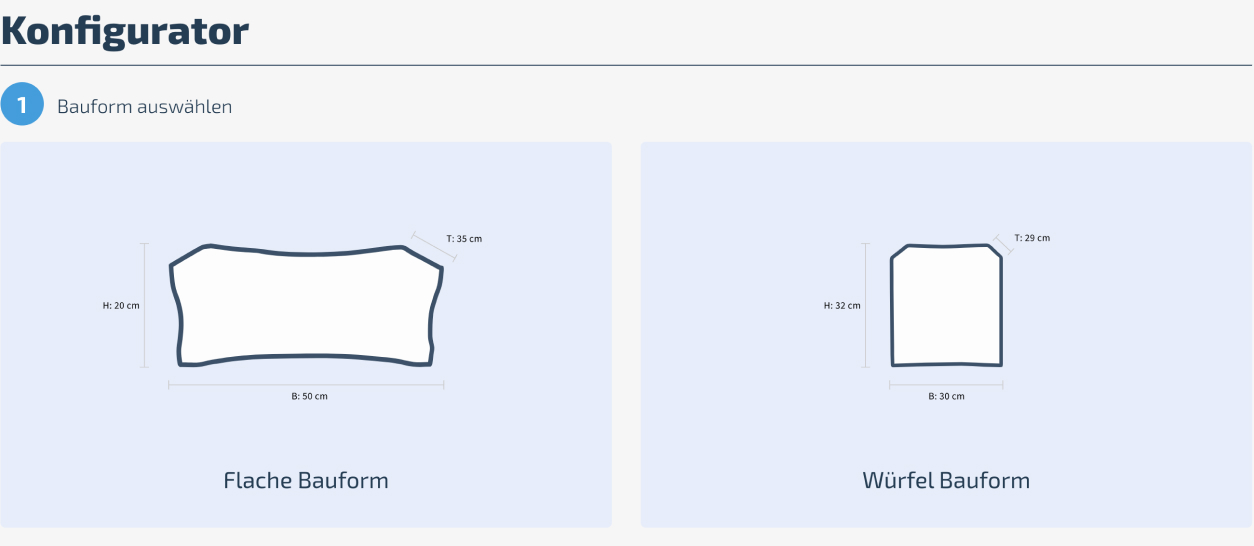

Create your own charger! The configurator for the Nordic Multiplex Charging Systems helps you with that. Switch to the latest Li-Ion technology now and still keep your existing tools, no matter which battery technology is in use!

Go to Configurator

The Battery Management Software (BMS) plays a central role in monitoring and optimizing battery systems. It enables real-time monitoring of voltage, charge status, and temperature to detect potential issues early. By precisely controlling charge and discharge cycles, the BMS software extends battery life and optimizes efficiency.

Users can monitor battery status and adjust settings. Overall, the BMS software is crucial for enhancing performance, safety, and cost minimization of battery systems.